Current location:Home > 34053 seal kit >

34053 seal kit

2025-08-15 01:39

2025-08-15 01:34

2025-08-15 01:06

2025-08-15 00:29

2025-08-14 23:50

2025-08-14 23:49

2025-08-14 23:46

2025-08-14 23:43

2025-08-14 23:30

2025-08-14 23:21

Latest articles

When selecting a hydraulic press seal kit, it's vital to consider the specific requirements of your equipment hydraulic press seal kit. Factors like the type of fluid being used, the operating pressure and temperature, and the speed of the press all influence the choice of seals. Moreover, regular inspection and timely replacement of worn or damaged seals are crucial to maintaining the optimal functionality of the hydraulic press.

hydraulic press seal kit. Factors like the type of fluid being used, the operating pressure and temperature, and the speed of the press all influence the choice of seals. Moreover, regular inspection and timely replacement of worn or damaged seals are crucial to maintaining the optimal functionality of the hydraulic press.

hydraulic press seal kit. Factors like the type of fluid being used, the operating pressure and temperature, and the speed of the press all influence the choice of seals. Moreover, regular inspection and timely replacement of worn or damaged seals are crucial to maintaining the optimal functionality of the hydraulic press.

hydraulic press seal kit. Factors like the type of fluid being used, the operating pressure and temperature, and the speed of the press all influence the choice of seals. Moreover, regular inspection and timely replacement of worn or damaged seals are crucial to maintaining the optimal functionality of the hydraulic press.The 'oil' in the name denotes the seal's compatibility with oil-based lubricants. It is typically made from materials like nitrile rubber (NBR), which offers excellent resistance to oils, heat, and pressure. The robust construction ensures durability even in harsh operating conditions The robust construction ensures durability even in harsh operating conditions The robust construction ensures durability even in harsh operating conditions The robust construction ensures durability even in harsh operating conditions

The robust construction ensures durability even in harsh operating conditions The robust construction ensures durability even in harsh operating conditions 35x72x10 oil seal.

35x72x10 oil seal.

The robust construction ensures durability even in harsh operating conditions The robust construction ensures durability even in harsh operating conditions

The robust construction ensures durability even in harsh operating conditions The robust construction ensures durability even in harsh operating conditions 35x72x10 oil seal.

35x72x10 oil seal.In addition to preventing the ingress of contaminants, dust lip seals also play a role in retaining lubricants within the system. Lubricants such as oil and grease are essential for reducing friction and wear between moving parts, helping to extend the lifespan of the equipment. Without an effective seal in place, these lubricants can leak out of the system, leading to insufficient lubrication and potential damage to the machinery. Dust lip seals help to maintain the proper levels of lubricant within the system, ensuring optimal performance and minimizing the risk of failure.

Installing an oil seal is a relatively simple process that can be done by following a few basic steps

20x30x7 oil seal. Firstly, the shaft and housing must be thoroughly cleaned to remove any dirt or debris that could interfere with the seal. The oil seal is then carefully placed over the shaft and pressed into the housing using a seal driver or a soft mallet to ensure a secure fit.

20x30x7 oil seal. Firstly, the shaft and housing must be thoroughly cleaned to remove any dirt or debris that could interfere with the seal. The oil seal is then carefully placed over the shaft and pressed into the housing using a seal driver or a soft mallet to ensure a secure fit.

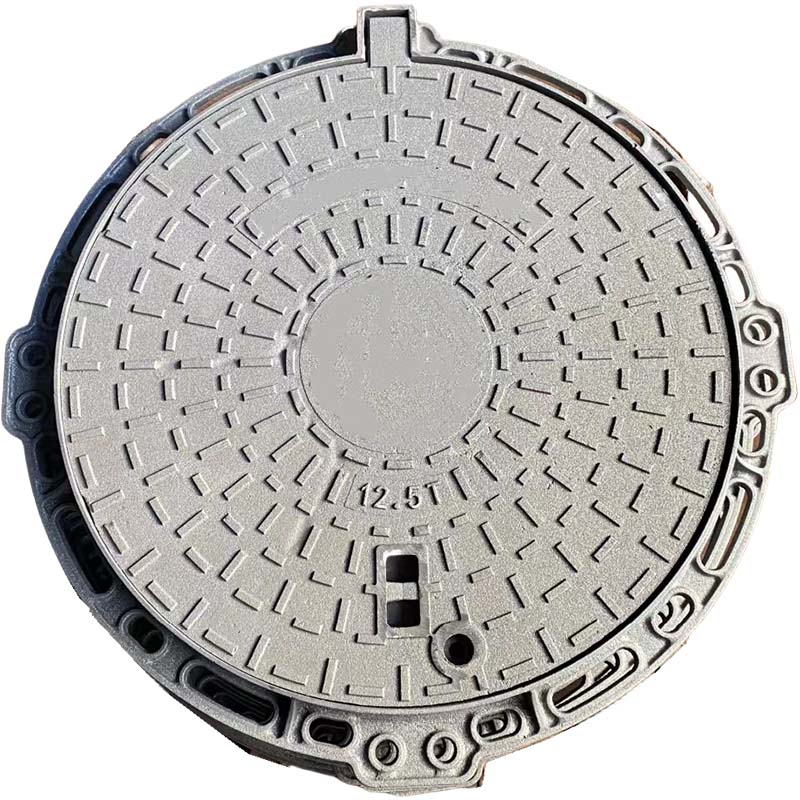

One of the primary materials used for manufacturing 600 x 500 manhole covers is cast iron, known for its durability and strength. These covers must withstand the heavy loads of traffic while maintaining their structural integrity. Advanced manufacturing techniques, including ductile iron and composite materials, are also making their way into the market. These innovations contribute to a reduction in weight while enhancing resistance to corrosion, therefore extending the lifespan of the covers.

600 x 500 manhole cover